Manufacturers

Representing the industry’s most innovative lines.

PMR WEST

PMR EAST

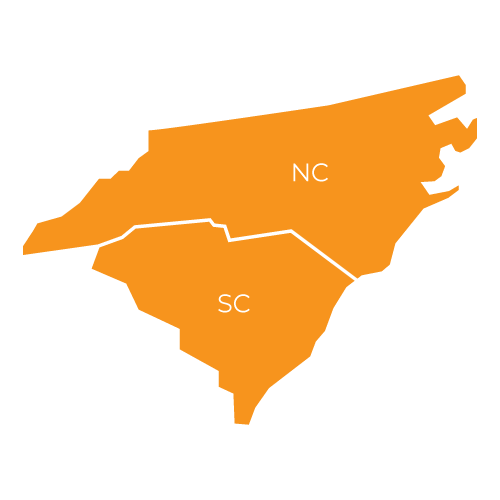

PMR CAROLINAS

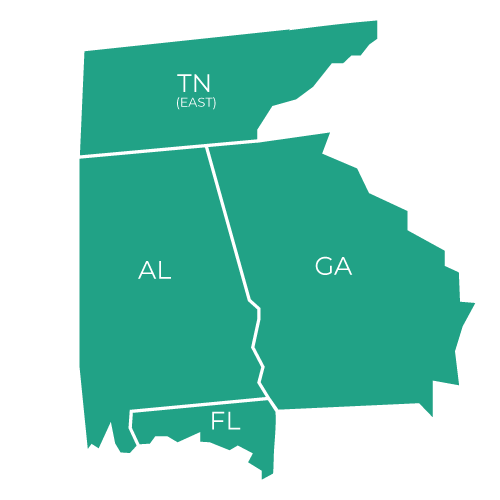

PMR EAST

DOWNLOAD LINE CARDPMR WEST

DOWNLOAD LINE CARDPMR CAROLINAS

DOWNLOAD LINE CARDready to learn more?

PMR IS HERE TO HELP!

Contact Info

1305 Lakes Parkway, Ste. 106

Lawrenceville, GA 30043

Toll Free: (800) 836-2716

Office: (770) 441-3100

Fax: (770) 449-6834