Welcome to the PMR Foodservice Blog

Getting the Best Cut From a Commercial Food Processor

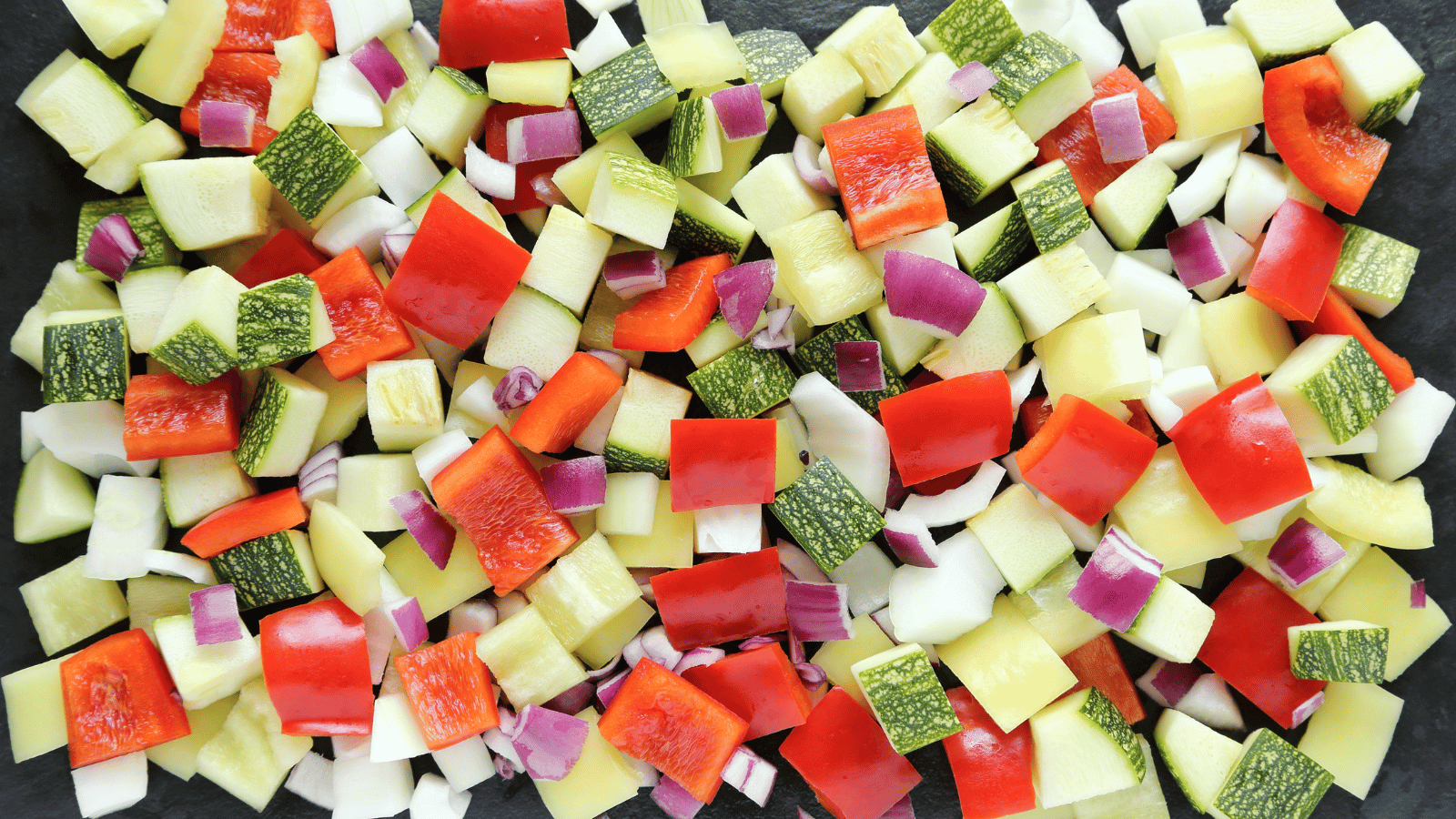

Chopping, slicing or dicing is one of the most difficult and time-consuming tasks in the kitchen. Hobart food processors are designed for maximum efficiency, adaptability and dependability, allowing chefs and other commercial kitchen staff to focus on other aspects of meal preparation.

How Do You Know Which Tool Is Best?

Not all food processors are built the same, so operators need to make sure they're buying the right model. There are several variables to consider when comparing different machines:

Assess Your Kitchen's Needs

Some restaurants must handle a large number of vegetables in a short amount of time for entrees, sauces, salads and other menu items. Smaller enterprises may just require a few batches of items to be chopped at a time. So, having a processor built for the right volume can ensure workers don't get backlogged.

Furthermore, the sorts of foods utilized and how they are processed make a difference. One processor, for example, may be ideal for chopping vegetables while another is ideal for slicing them into tiny slices. It is critical to know exactly what the commercial food processor will be used for when choosing the proper model.

Choose the Right Size and Capacity

Using a little food processor can stymie the job of any kitchen staff member. Choose a size that is large enough for growth but not so little that the chopping process is often halted to swap out bowls.

Look for Power and Performance

Keep an eye out for wattage and additional tools that can help staff complete their jobs faster. The higher the wattage, the more it can handle in terms of quantities and speed. Operators should also pay close attention to the width of the tube used to feed ingredients into the food processor. A small tube works well for longer items, like carrots, while a wide-mouth opening is best for potatoes and other larger ingredients.

Consider Blades and Attachments

It's unrealistic to assume that a kitchen will only need to slice, dice or chop its food. Hobart food processors come with different blade attachments to achieve specific results, including kneading, pureeing, mixing and more. Making the food processor more efficient and helping to cut back on how many pieces of equipment are needed in each kitchen.

Ease of Use and Controls

Hobart food processors, fortunately, are as simple to use as anything else in a professional kitchen. Everything from running the machine to switching the blades is designed to be as efficient as possible. Even kitchens with a relatively high turnover can swiftly train new personnel, saving on labor expenses.

Durability and Ease of Cleaning

Hobart food processors are toughly constructed, featuring stainless steel components and non-slip feet. They are capable of handling continuous processing for as long as necessary without the need for continual maintenance or upkeep.

And cleaning these processors is a breeze whether the kitchen processes a few pounds of food or a few hundred pounds. All it takes is removing and cleaning the blades and wiping down the interior so workers can use them frequently and efficiently all day is easy without cross-contamination.

Hobart Food Prep Solutions: An Option for Every Commercial Kitchen

Having a variety of options available allows each foodservice business to customize the Hobart food processor model that works best for their kitchen. From schools to hospitals to QSRs, there is a unit for every need.

Countertop Continuous Feed Processors

Smaller units can process up to 11 pounds of ingredients per minute, while larger versions can handle up to 17 pounds a minute. These processors also don't take up too much space, making them ideal for cramped kitchens or mobile operations.

Hobart also offers bowl-style processors that can chop and mix simultaneously. Food cutters can also yield impressive results for salads and other dishes that require uniform slicing of different ingredients.

Floor Model Continuous Feed Processors

A floor model can slice, chop, or dice up to 132 pounds of food per minute for kitchens that need to serve hundreds of people quickly. When every second counts, these machines are ready to handle any challenge.

Plus, they can have fixed or rolling wheels, so chefs can deploy them wherever they're needed most.

Best of all, operators can even calculate their productivity levels to ensure they're getting the right size for their kitchen.

Discover how using the best dicing, slicing, and mincing tools can help your commercial kitchen prosper:

Subscribe Here!

Lists by Topic

- Restaurants (23)

- PMR Preview (18)

- K-12 School Nutrition (12)

- Beverage (8)

- Vulcan (8)

- Healthcare (5)

- Hospitality (5)

- Ovention (5)

- Duke (4)

- Perlick (4)

- Traulsen (4)

- Trends (4)

- Ventless (4)

- Winco (4)

- Carlisle Foodservice (3)

- Convenience Store (3)

- Food Safety (3)

- Hatco (3)

- ITW (3)

- PMR (3)

- RATIONAL (3)

- Waring (3)

- Bakery (2)

- College & University (2)

- General (2)

- Griddle (2)

- Prince Castle (2)

- Spaceman (2)

- Takeout & Delivery (2)

- Thermo-Kool (2)

- Araven (1)

- Charbroiler (1)

- Choice Equipment Company (1)

- Correctional (1)

- Dinex (1)

- Dish Machines (1)

- Frying (1)

- G.E.T. Serveware (1)

- Hobart (1)

- Holidays (1)

- QSR (1)

- Recipe (1)

- Silver King (1)

- Titan Stainless Steel (1)