Welcome to the PMR Foodservice Blog

Trends and Innovations in On-site Foodservice Cafeterias

On-site cafeterias are evolving quickly, whether they are serving students, employees, or community guests. Expectations for variety, speed, and sustainability are pushing operators to rethink traditional models. These dining spaces have become hubs for efficiency and innovation, with plant-based options, eco-friendly equipment, and technology leading the way.

The challenge now is how operators can translate these emerging trends into everyday service without overburdening staff or straining budgets.

Food Variety and Speed for High-Volume Service

Guests today expect more than the standard tray line. From business dining to school cafeterias, demand for grab-and-go meals and plant-forward choices is reshaping menu planning and kitchen design. Variety has to come without slowing down service, which means rethinking menus and workflows to balance creativity with consistency.

Serving systems like Duke’s CounterCraft give operators flexibility to rotate menus and handle traffic efficiently. In practice, that means cafeterias can offer a broader range of options, from hearty entrees to lighter, plant-based dishes, while keeping lines moving. What feels like freedom of choice to customers is, for staff, a system built to run smoothly under pressure.

Sustainability in On-site Dining

Sustainability has moved from a talking point to a requirement. Organizations of every type are under pressure to cut waste, reduce energy use, and demonstrate environmental responsibility. For cafeterias, equipment choices often carry the most impact.

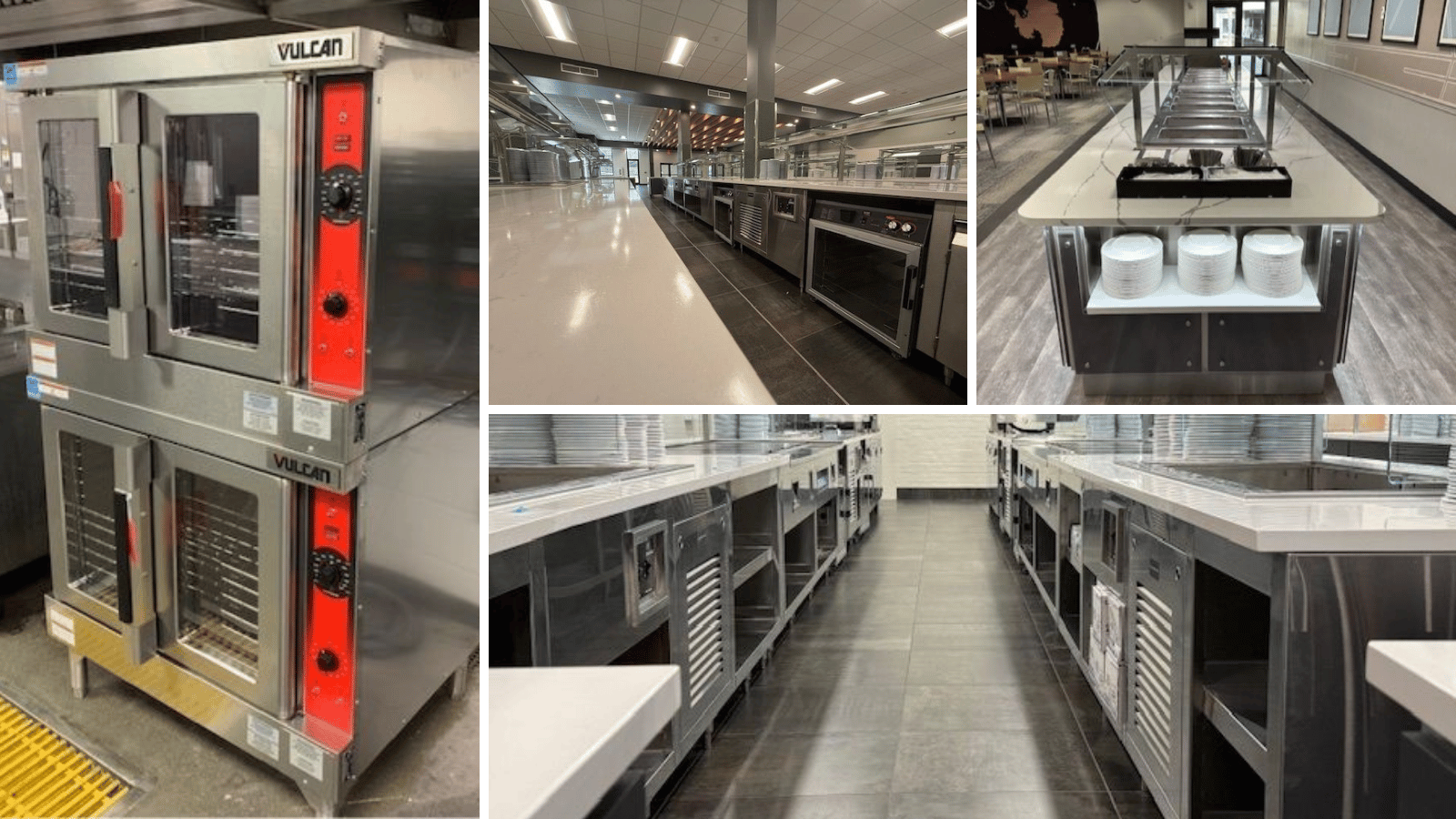

Manufacturers are tackling this with more innovative equipment and automation. Vulcan’s combi ovens prepare multiple menu types in a single unit with lower energy demand. Hatco brings energy-conscious design to serving lines and beverage service. Refrigeration upgrades help operators reduce food waste while saving on utilities. Sustainability is not only about optics. It is about long-term cost control and operational resilience.

Technology Integration for Efficiency

Labor is tight across foodservice, and on-site cafeterias are no exception. Smart technology is helping fill the gap. Programmable cooking equipment ensures consistency with less training time. Automated beverage systems reduce bottlenecks at peak hours. Data-driven serving lines monitor traffic and alert staff when replenishment is needed.

The result is less manual oversight and more reliable service. For operators, that kind of efficiency keeps teams moving even when staff is stretched thin.

Real-World Examples from PMR Projects

PMR’s recent projects illustrate how these trends play out beyond the page.

Vulcan VP18 holding cabinets were installed at Douglasville Town Green, alongside double-stack ovens and combi ovens to support large-volume events. The equipment combination ensures food quality and speed of service for a broad community audience.

At the Ridgecrest Conference Center in North Carolina, collaboration between Stipe Consulting and Duke’s CounterCraft highlighted how flexible serving solutions can meet both operator and guest needs in a dynamic dining environment.

At the Ridgecrest Conference Center in North Carolina, collaboration between Stipe Consulting and Duke’s CounterCraft highlighted how flexible serving solutions can meet both operator and guest needs in a dynamic dining environment.

Pensacola Christian College's campus installation balanced durability with high-volume performance, showing how cafeterias can meet student expectations without overextending resources.

Each of these examples underscores PMR’s ability to connect clients with solutions that align with today’s on-site dining priorities, including variety, sustainability, and efficiency.

Be on trend at your on-site cafeteria - take our foodservice assessment to get started:

Subscribe Here!

Lists by Topic

- Restaurants (23)

- PMR Preview (18)

- K-12 School Nutrition (12)

- Beverage (8)

- Vulcan (7)

- Healthcare (5)

- Hospitality (5)

- Ovention (5)

- Duke (4)

- Trends (4)

- Ventless (4)

- Winco (4)

- Convenience Store (3)

- Food Safety (3)

- Hatco (3)

- ITW (3)

- PMR (3)

- Perlick (3)

- Traulsen (3)

- Waring (3)

- Bakery (2)

- Carlisle Foodservice (2)

- College & University (2)

- General (2)

- Griddle (2)

- Prince Castle (2)

- RATIONAL (2)

- Spaceman (2)

- Takeout & Delivery (2)

- Thermo-Kool (2)

- Araven (1)

- Charbroiler (1)

- Choice Equipment Company (1)

- Correctional (1)

- Dinex (1)

- Dish Machines (1)

- Frying (1)

- G.E.T. Serveware (1)

- Hobart (1)

- Holidays (1)

- QSR (1)

- Recipe (1)

- Silver King (1)

- Titan Stainless Steel (1)